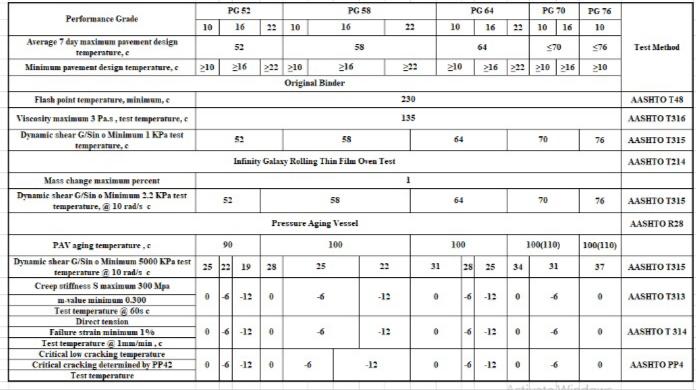

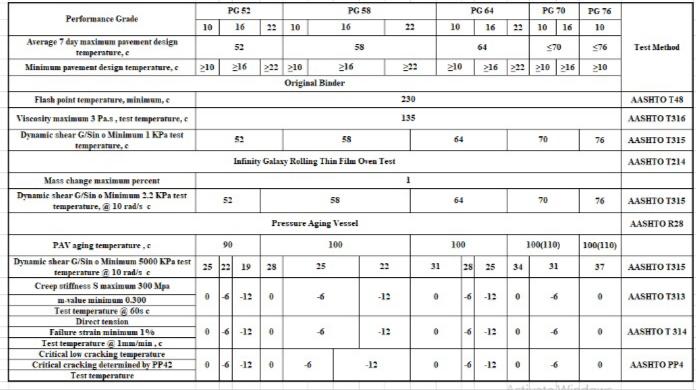

Bitumen Performance Grade is a type of bitumen which is graded according to its performance at different alternating temperatures.

There is a tendency to divide PG grade into two divisions of high-temperature and low temperature pavement services.

Here comes the major issue for high-temperature performance which is rutting, that normally takes a while to amass.

Thus, the temperature is measured within a week and the highest is considered to be the high climatic temperature.

On the other side, there is a possibility for thermal cracking at low temperature.

For both high and low temperature, PG grades are graded in 6 c rise.

The average seven-day maximum pavement temperature typically changes from 46 c to 82 c and the minimum pavement temperature changes from -46 c to -10 c.

For instance, bitumen PG 64-10 meets performance factor at an average seven-day maximum pavement temperature of 64 c also at a minimum pavement temperature of -10c.

Mind the point that maximum pavement temperature is usually higher than the air temperature by about 20c because the dark color of pavement absorbs the heat and keep it. As PG grades are mainly divided into Modified and Unmodified bitumen types, keep in mind the following hint which helps to differentiate the mentioned types.

To distinguish the modified from unmodified bitumen, we add both low and high-temperature grades together. If the sum is greater than 90, the substance is likely to be a polymer modified binder. As an example, a PG 76-22 is considered as a polymer-modified binder since the sum is 98. Another example, a PG 64-10 is an unmodified binder.

PG grades generally are mostly applied in paving constructions and reconstructions, sealing of edges, crack sealing, spray applications for bridge deck and in both dense graded and open-graded Hot Mix Asphalt (HMA).

PG grades which are well-structured against thermal cracking are PG 58-34, PG 64-22, PG 64-28 and PG 76-22.

PG grades which are resistant to rutting are PG 70-22, PG 70-28, PG 76-28 and PG 82-22.

PG 58-28 is specifically used in very cold regions.

There is a tendency to divide PG grade into two divisions of high-temperature and low temperature pavement services.

Here comes the major issue for high-temperature performance which is rutting, that normally takes a while to amass.

Thus, the temperature is measured within a week and the highest is considered to be the high climatic temperature.

On the other side, there is a possibility for thermal cracking at low temperature.

For both high and low temperature, PG grades are graded in 6 c rise.

The average seven-day maximum pavement temperature typically changes from 46 c to 82 c and the minimum pavement temperature changes from -46 c to -10 c.

For instance, bitumen PG 64-10 meets performance factor at an average seven-day maximum pavement temperature of 64 c also at a minimum pavement temperature of -10c.

Mind the point that maximum pavement temperature is usually higher than the air temperature by about 20c because the dark color of pavement absorbs the heat and keep it. As PG grades are mainly divided into Modified and Unmodified bitumen types, keep in mind the following hint which helps to differentiate the mentioned types.

To distinguish the modified from unmodified bitumen, we add both low and high-temperature grades together. If the sum is greater than 90, the substance is likely to be a polymer modified binder. As an example, a PG 76-22 is considered as a polymer-modified binder since the sum is 98. Another example, a PG 64-10 is an unmodified binder.

PG grades generally are mostly applied in paving constructions and reconstructions, sealing of edges, crack sealing, spray applications for bridge deck and in both dense graded and open-graded Hot Mix Asphalt (HMA).

PG grades which are well-structured against thermal cracking are PG 58-34, PG 64-22, PG 64-28 and PG 76-22.

PG grades which are resistant to rutting are PG 70-22, PG 70-28, PG 76-28 and PG 82-22.

PG 58-28 is specifically used in very cold regions.

Viscosity grade bitumen:

in four different types including VG10, VG20, VG30 and VG40 is the most widely used bitumen in India, which has been replaced by bitumen penetration grade according to the Indian Standard (IS:73).This kind of bitumen is more reliable than others due to its advantages and properties.

In the following, we will tell you more about the applications, descriptions and specification of each grades, and you will find the best VG bitumen that you need.

VG 10 Bitumen

VG 20 Bitumen

VG 30 Bitumen

VG 40 Bitumen

What is the difference between penetration grade bitumen and viscosity grade bitumen?

The difference between penetration grade bitumen and viscosity grade bitumen is that the penetration grade classification is based on the Penetration value in 25 ◦C, while VG system is based on Viscosity value in both 60 ◦C and 135 ◦C that shows it is suitable for both low and high temperature so the bitumen behavior in different thermal conditions can be predicted well.

Classification of Viscosity Grade Bitumen

Viscosity test on bitumen results the classification of bitumen in a range of grades, including VG10 Bitumen, VG20 Bitumen, VG30 Bitumen, and VG40 Bitumen.

The higher the number, the harder the bitumen in the viscosity grading system.

To know more about VG’s specification and comparison of the properties of grades, see the table at the end of the article.

Viscosity grade Standards

Viscosity Grade bitumen is determined by IS 73, ASTM and AASHTO.

According to the IS, grading of Bitumen is changed from penetration grade to viscosity grade in 2006.

Read the article to understand the viscosity grade bitumen definition, applications and specifications.Viscosity grade Standards

Viscosity Grade bitumen is determined by IS 73, ASTM and AASHTO.

According to the IS, grading of Bitumen is changed from penetration grade to viscosity grade in 2006.

Read the article to understand the viscosity grade bitumen definition, applications and specifications.

Application of viscosity grade bitumen

Generally, each of these viscosity grade bitumen has different application according to the two important factors such as climate and traffic conditions.

The important use of VG bitumen is due to the existence of two important properties of this material which are water impermeability and high adhesion.

Today, more than 250 different applications for VG bitumen have been considered that it seems to be impossible to replace them with other materials.

In the table you can see different applications and properties of VG bitumen.

Application of viscosity grade bitumen:

| Grade | Viscosity Range at 60°C (Absolute Viscosity) | Typical Applications |

| VG-10 Bitumen | 800-1200 | Recommended for road construction in cold regions |

| Ideal for spraying | ||

| Used in production of bitumen emulsion | ||

| VG-20 Bitumen | 1600-2400 | Used in cold regions for road construction |

| VG-30 Bitumen | 2400-3600 | Maximizes asphalt performance in hot regions |

| A more reliable choice than bitumen pen 60/70 | ||

| VG-40 Bitumen | 3200-4000 | Works in areas with high traffic loads |

| Well suited for road construction in hot weather |

Advantages of viscosity grade bitumen:

Nowadays, VG bitumen is used instead of penetration bitumen, because it is tested more carefully in two phases by experts. First, the penetration of bitumen is measured at 25 ◦C that is the average temperature, but the results of this test is not reliable in the hot weather, so they measure the viscosity of bitumen at 60 ◦C and 135 ◦C. These tests tell us that:

1- VG bitumen is suitable for a wide range of temperature; 25 ◦C for fatigue cracking and 135 ◦C for construction , also temperature susceptibility can be determined

2- Less number of tests save time and costs; according to IS it has only 7 tests while penetration has 14 tests.

3- Longer durability: the pavement made from VG Bitumen will have better performance, because Viscosity value at 135 C gives sufficient idea about mixing and compaction temperature and as a result pavement life is improved.

4- Any two samples of same VG bitumen would give similar rutting performance in hot summer unlike the penetration grade

5- Minimum specified kinematic viscosity value at 135 C helps to minimize the potential of tender mixes during construction

6- VG bitumen is suitable for areas with high traffic loads

Viscosity grade bitumen is a petroleum grade bitumen derived from crude oil. This grade of bitumen is tested and classified differently from other types of bitumen. After production, refiners test the VGs by a viscometer to classify them according to their level of viscosity in various temperatures.

The viscosity test results in four VG grades of bitumen including VG10 Bitumen, VG20 Bitumen, VG30 Bitumen, and VG40 Bitumen. The higher the number, the harder the bitumen in the viscosity grading system.

In comparison to penetration grade bitumen, VG bitumen grades are more reliable and easier to handle (both mixing and compaction) and their resistance to temperature changes is more predictable.

Read the article to find out each VG bitumen grade’s description, applications, and specifications. Or use the below links to read the section you need.

Blown Asphalt 75/35

Blown Asphalt 75/35 is an oxidized Bitumen produced by oxidizing a selected petroleum asphalts without adding the catalyst. Chemical Mine World Oxidized Bitumen 75/35 has high softening point, high flash point and it is highly stable during melting.

This kind of Blown Asphalt is mostly using in the Mediterranean and specially morocco market.

Blown Asphalt 75/35 is produced by the air-blowing of penetration grade bitumen.

This is done at high temperatures, resulting in a material of a much higher penetration index.

Chemical Mine World Oxidized Bitumen 75/35 is based on petroleum bitumen which is made by blowing bitumen 60/70 by very hot air.

The designation of the Oxidized bitumen 75/35 refers to the midpoint of the softening point acceptance criteria.

Blown Asphalt is a solid or semi-black solid material and gradually liquid when heated.

Oxidized Bitumen grades are blown or oxidized bitumen ‘s which are produced by passing air through soft bitumen under controlled temperature conditions.

This process gives the bitumen more rubbery properties than penetration or hard grade bitumen's and a variety of uses in industrial applications.

Chemical Mine World Oxidized Bitumen 75/35 is produced by either Continuous or Staggered Blowing Process.

Heated Penetration Grade Bitumen under controlled environment is blown with air which controls the Oil Content in the Bitumen while it oxidized.

The different grades for suited applications produced are designated by two numbers to indicate the mid-points of their softening point and penetration ranges.

Oxidized Bitumen 75/35 is based on petroleum bitumen which is made by blowing bitumen 60/70 by very hot air. In addition, the numbers relate to the midpoint of the material’s softening point and penetration respectively. The softening point value measured by Ring and Ball method as determined by ASTM D36. Also, the penetration value is in 1/10 mm as determined by IP 49 or ASTM- D5.

Application of Blown Asphalt 75/35:

Blown Asphalt 75/35 grades are produced by passing air through soft bitumen under controlled temperature conditions. This process gives the bitumen more rubbery properties than penetration or hard grade bitumen and enables the product to serve a variety of uses in industrial applications. These grades are suitable for sealing saw cuts and joints where there is expected to be the minimum amount of moving in the joint. Their wide temperature range prevents bleeding in high-temperature applications. They can also be used for industrial applications such as pipe coating, roofing, waterproofing, flooring, mastics, sound damping, carpet backing, adhesive and electrical applications. Hard bitumen under controlled temperature conditions is widely used as an anti-slip layer compound in the piling industry, for the manufacture of roofing felts, the roofing and waterproofing industries, for sound dampening felts and under carriage sealant in the automotive industry, electric cable joint protection, joint filling compound, sealant compound, and many others. Also used in sealing saw cuts and joints where expected movements are minimum.

Technical Advantages of Blown Asphalt 75/35

- Durability

- Flexibility

- Water Resistant

- Chemical Stability

Compared to paving grade bitumen:

- Reduced temperature susceptibility

- Exhibits a more ‘solid’ nature at ambient temperatures

- High penetration index

Handling / Storage:

Heating of packaged bitumen is a critical phase in most of the final uses. Typically, the packaged material is heated and melted in boilers out on site.

However, control at the heating phase is very important in terms of health and safety as well as in maintaining the quality of the product.

Note must be taken of the maximum safe handling temperature of 230 C and this should not be abused. Bitumen is a poor conductor of heat, consequently, control of the heating phase is of paramount importance.

The Oxidized Bitumen material should be broken up prior to placement in the boiler. This exposes a larger surface area to the heat and encourages a more even heating regime.

Without the larger exposed surface area, aggressive heating at the base and sides of the boiler may well result in localized overheating, altering the characteristics of the Chemical Mine World modified bitumen and potentially causing thermal cracking of the bitumen, creating the release of low lash vapors.

The flash point of the oxidized bitumen then becomes irrelevant; as these low flash vapors determine the fire risk.

Melted bitumen should not be left in the boiler and reheated from cold, as there is then a high potential for localized overheating around the heating area (lack of convection means poor heat transfer) and potential development of a pressurized pocket of low flash vapors.

Be aware of the placement of any temperature monitoring or control devices.

As a result of the poor thermal conductivity of the bitumen, a thermometer in the bitumen some distance from the heat source could read significantly different (even hundreds of degrees) from the true temperature of the bitumen near the heat source.

For Health and Safety information, please make reference to the relevant MSDS.

Health & Safety:

Workers should wear protective masks, gloves, and goggles during application. The asphalt can be removed from equipment and tools with kerosene or gasoline. Care should be taken when heating Blown Asphalt 75/35 to avoid over heating

Packing of blown asphalt 75/35:

The Chemical Mine World is manufacturer of blown asphalt 75/35 in various packing including kraft bag, meltable plastic bag, drum and bulk blown asphalt 75/35 from penetration grade bitumen, which is blown by hot air in a controlled process until the desired specification is reached.the Chemical Mine World oxidised bitumen 75/35 can be supplied in any grade and are designated by two numbers to indicate the softening point and penetration ranges. The blown asphalt grade 75/35 means softening point is 75°c and penetration is 35 desimillimiter is produced in compliance and conformity to ASTM standard and meets the following specification.

Data Sheet of Blown Asphalt 75/35:

| Bitumen 75/35 | Test method | Unit | Specification |

| Specific gravity @25/25 C | ASTM D70 | (Kg/m3) | 1.05 approx. |

| Penetration @ 25°c | ASTM D5 | mm/10 | 30/40 |

| Softening point °c | ASTM D36 | °C | 70/80 |

| Loss on heating(wt) % | ASTM D6 | Wt. % | 0.2 max |

| Flash point c | ASTM D92 | °C | 250 min |

| Solubility is CS2(wt) % | ASTM D4 | Wt. % | 99.5 max |

| Spot test | A.A.S.H.T.O 102 | — | Negative |