SPECIFICATION BITUMEN AH-110:

| SPECIFICATION OF BITUMEN AH-130 | |||

| SPECIFICATION | UNIT | VALUE | TEST METHOD |

| Penetration, 25°C | 1/10 Millimetres (mm) | 80-130 | ASTM D5 |

| Softening Point | Degree Celsius (°C) | 45-52 | ASTM D36 |

| Density, 25°C | Kilogram per Cubic Meter (kg/m³) | 1.000 min | ASTM D71/D3289 |

| Ductility, 25°C | Centimetres per Second (cm/s) | 100 min | ASTM D113 |

| Loss On Heating | Weight Percentage (WT%) | 0.5 Max | ASTM D6 |

| Drop-in Penetration After Heating | Percentage (%) | 20 Max | ASTM D6805 |

| Flash Point (Cleveland Open Cup) | Degree Celsius (°C) | 225 min | ASTM D92 |

| Solubility in Trichloroethylene | Weight Percentage (WT%) | 99 min | ASTM D2042 |

| Loss of Weight | Percentage (%) | 0.8 max | ASTM D1754 |

| Retained Penetration After Thin Film | Percentage (%) | 50 min | ASTM D5 |

| Ductility 25°C After Thin Film Oven | Centimetres per Second (cm/s) | 100 min | ASTM D113 |

| Ductility 15°C After Thin Film Oven | Centimetres per Second (cm/s) | 100 min | ASTM D113 |

| Temperature | Degree Celsius (°C) | Max 90-110 above the Soft | |

| Bitumen Content | Percentage (%) | 99.9 min | ASTM D |

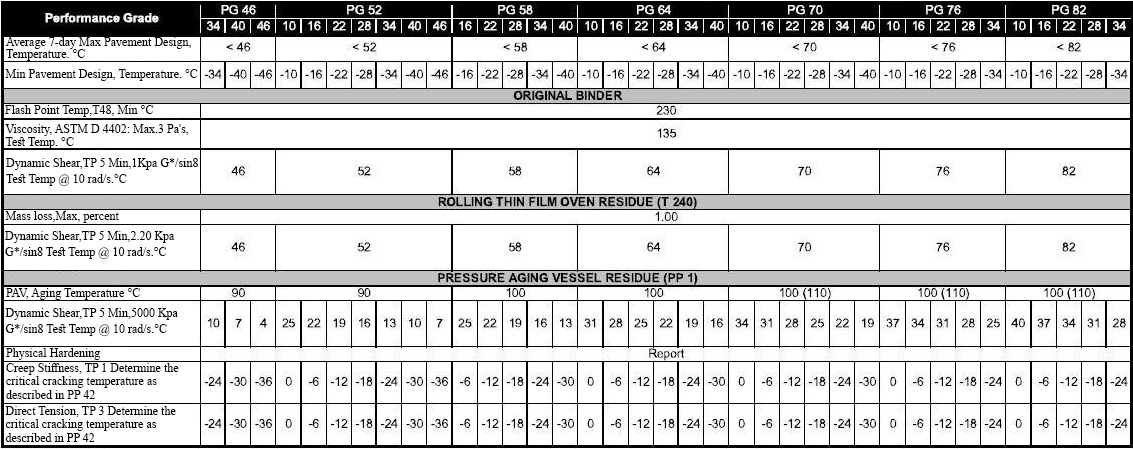

BITUMEN PG

Performance Grade (PG) bitumen is graded based on its performance at different temperatures.It is new method bitumen standard which based on varying temperatures. This method studies the mechanical specifications of bitumen.

Since in this method, a temperature range is defined for bitumen, the consumer can easily choose the desired product.

Performance Grade is determined for polymer modified bitumen and pure bitumen based on environmental conditions and temperature.

The wider PG range the higher resistance and more favorable specifications.

Chemical Mine World has the capability to supply customers a wide range such as PG 46, PG 52, PG 58, PG 64, PG 70, PG 76, PG 82.

Application of Performance Grade (PG) Bitumen:

PG 52-28 is primarily used in paving for both new construction and pavement rehabilitation and in both dense-graded and open graded Hot Mix Asphalt (HMA). This product could also be used for sealing of edges of new to told paving and crack sealing. Other uses include spray applications for bridge deck and pavement protective membrane with fabrics.

PG 58-22 is primarily used in paving for both new construction and pavement rehabilitation and in both dense-graded and open graded Hot Mix Asphalt (HMA). This product could also be used for sealing of edges of new to told paving and crack sealing. Other uses include spray applications for bridge deck and pavement protective membrane with fabrics.

PG 58-28 is primarily used in paving for both new construction and pavement rehabilitation and in both dense-graded and open-graded HMA. Other uses include spray applications for bridge deck and pavement protective membrane with fabrics. PG 58-28 is generally used in very cold areas.

PG 58-34 is generally used in the upper half of eastern Washington and on higher elevation roadways. PG 58-34 is a paving asphalt cement primarily used for the production of Hot Mix Asphalt (HMA). This product could also be used for sealing the edges of new to old paving and crack sealing.

PG 58-34 is used in paving for both new construction and pavement rehabilitation in both dense-graded and open-graded HMA.

PG 58-40 is primarily used on the high elevation roadways. PG 58-40 is paving asphalt cement for the production of Hot Mix Asphalt (HMA).

This product could also be used for sealing of edges of new to old paving and crack sealing.

PG 64-22 is primarily used in paving for both new construction and pavement rehabilitation and in both dense-graded and open graded Hot Mix Asphalt (HMA). This product could also be used for sealing of edges of new to old paving and crack sealing. Other uses include spray applications for bridge deck and pavement protective membrane with fabrics. It has been reported that with proper aggregate characteristics and asphalt content, HMA with PG 64-22 as the binder may exhibit less tenderness than a similar mixture with a lower viscosity/softer asphalt. The typical tenderness problems of mixture shoving and checking during rolling and pavement surface scuffing and marking by traffic immediately after paving may be noticeably reduced.

PG 64-28 is primarily used in paving for both new construction and pavement rehabilitation and in both dense-graded and open-graded HMA.

Other uses include spray applications for bridge deck and pavement protective membrane with fabrics. PG 64-28 is generally used for the Lower half of Eastern Washington.

PG 70-22 is primarily used in high traffic areas and is also the paving asphalt cement primarily used for the production of Hot Mix Asphalt (HMA).

This product could also be used for sealing the edges of pavement and for crack sealing.

SPECIFICATION FOR PERFORMANCE GRADE BITUMEN:

Oxidized Bitumen 105-15:

Oxidized Bitumen 105-15 created by further vigorous air process another names of it is blown asphalt 105/15, oxidized bitumen 105/15, hard bitumen. It also is Semi Solid grade of pure petroleum bitumen made by air-blowing through an asphalt flux. Because of physical specs it uses in construction.

Passing air through bitumen at elevated temperature can used to alter its physical properties.

Degree of oxidation ranges from very small, or semi-blowing, through to “full” blowing. Bitumen specs are significantly different to penetration grade bitumen.

Nomenclature and grading for the oxidized bitumen products is based on a combination of temperature. At which bitumen reaches a certain “softness” when being heated up as expressed by ring and ball softening point test, and the penetration value

As said before, Oxidized asphalt 105/15 is based on petroleum bitumen which is made by blowing bitumen 60/70 by very hot air.

In addition the numbers relate to the midpoint of material’s softening point and penetration respectively.

The softening point value measured by Ring and Ball method as determined by ASTM D 36.

Also penetration value is in 1/10 mm as determined by IP 49 or ASTM- D5.

Also currently Oxidized Bitumen oil refining method, breaking residue production is the use of 2 different sets of process equipment will produce qualified products according to different market and season demand. Probably, this production isn’t only huge investment, however conjointly waste a lot of high quality heat.

Application of Oxidized asphalt 105/15:

Oxidized asphalt 105/15 uses in the chemical, fuel, paints, lacquers, varnishes, paper-pulp-board, textile processing, road construction, pavement ,crack seal and repairmen, civil works, roofing, construction industries; sealing and insulating buildings, adhesive, construction materials additive, dust-binding, coating, insulating and impregnating agent, make rubber and plastic products. The blown asphalt 105/15 products are for paving, roofing; also used in asphalt based paints for corrosion protection of metals, in lining public works structures, adhesives in electrical laminates, base for synthetic turf; typical uses for oxidized asphalt 105/15 include roofing, pipe coating, Portland cement pavement, hydraulic applications, paint manufacturing.

Technical Advantages of Blown Bitumen 105/15:

- Durability

- Flexibility

- Water Resistant

- Chemical Stability

Storage and Handling:

Heating of packaged bitumen is a critical phase in most of the final uses. Typically, the packaged material is heated and melted in boilers out on site.

However, control at the heating phase is very important in terms of health and safety as well as in maintaining the quality of the product.

Note must be taken of the maximum safe handling temperature of 230 C and this should not be abused. Bitumen is a poor conductor of heat, consequently, control of the heating phase is of paramount importance.

The Blown Bitumen material should be broken up prior to placement in the boiler. This exposes a larger surface area to the heat and encourages a more even heating regime. Without the larger exposed surface area, aggressive heating at the base and sides of the boiler may well result in localized overheating, altering the characteristics of the Chemical Mine World modified bitumen and potentially causing thermal cracking of the bitumen, creating the release of low lash vapors.

The flash point of the oxidized bitumen then becomes irrelevant; as these low flash vapors determine the fire risk.

Melted bitumen should not be left in the boiler and reheated from cold, as there is then a high potential for localized overheating around the heating area (lack of convection means poor heat transfer) and potential development of a pressurized pocket of low flash vapors.

Be aware of the placement of any temperature monitoring or control devices. As a result of the poor thermal conductivity of the bitumen, a thermometer in the bitumen some distance from the heat source could read significantly different (even hundreds of degrees) from the true temperature of the bitumen near the heat source.

For Health and Safety information, please make reference to the relevant MSDS.

Health & Safety:

Workers should wear protective masks, gloves, and goggles during application. The asphalt can be removed from equipment and tools with kerosene or gasoline. Care should be taken when heating Blown Bitumen 105/15 to avoid over heating

Datasheet of Oxidized Asphalt 105/15:

| Bitumen 105/15 | Test method | Unit | Specification |

| Specific gravity @25/25 C | ASTM D70 | (Kg/m3) | 1.05 approx. |

| Penetration @ 25°c | ASTM D5 | mm/10 | 10-20 |

| Softening point °c | ASTM D36 | °C | 100/110 |

| Loss on heating(wt) % | ASTM D6 | Wt. % | 0.2 max |

| Flash point c | ASTM D92 | °C | 250 min |

| Solubility is CS2(wt) % | ASTM D4 | Wt. % | 99.5 max |

| Spot test | A.A.S.H.O.T102 | — | Negative |